Products

To See Pricing, Register Now

24 Channel Module

Product code: NRTRB24F

The Rapid Test 24 Channel Module allows for the connection for up to 24 RCD’s…

Wi-Fi Master Module with Inbuilt 8 Channel Module 10mA / 500mA range

Product code: NRTMC8F5

Designed for smaller applications and larger milliamp ranges, the Rapid Test Systems Master Module with…

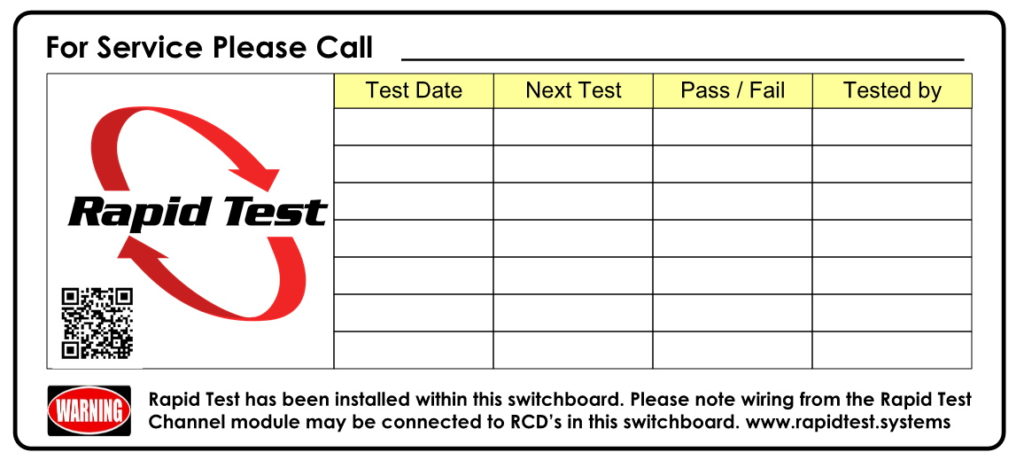

Switchboard Sticker Pack

Product code: RT005

Stickers can be applied to the door of the switchboard to clearly identify that Rapid…

How do i install rapid test?

Rapid Test modules should only be installed by a qualified and licensed electrician with suitable training in the operation and set up of this equipment.

All wiring must be of suitable electrical rating for the installation purpose and must comply with local regulations. Connection and disconnection of Rapid Test modules should only be done with switchboard power turned off.

Rapid Test is suitable for use with any existing RCD.

Modules may be installed within a switchboard enclosure and do not need a separate enclosure of their own unless space is limited within the switchboard

NEVER ATTEMPT TO CONNECT OR DISCONNECT ANY RAPID TEST DEVICE WITH POWER TURNED ON

Rapid Test Installation Notes

1.The RTTUWFM unit is capable of managing up to 10 RTRB24F modules in close proximity to the RTTUWFM. The RTMC8F5 is capable of managing up to 9 RTRB24F modules in close proximity to the RTMC8F5.

2. The installer must fix supply cables in the distribution board using cable ties or ducting as required by local wiring rules. Care must be taken not to allow copper strands to enter the RT unit’s apertures

3. A maximum torque of 1.4Nm should be applied to the mains rated screw terminals.

4. Rubber dust covers (RTSDC) should be inserted in unused RJ45 connectors, to stop foreign bodies from entering the unit. Always ensure these covers are installed when the unit is to be mounted inside a mains rated enclosure.

5. Use copper wire only

6. Do not attempt to open any Rapid Test module as they do not contain any user serviceable parts.

7. Rapid Test is certified to AS/NZS 3100:2009, and EMC compliant.

8. The channels modules must be installed in such a manner as to avoid vibration and shock.

Rapid test warranty

Limited Warranty

Rapid Test Systems expressly warrants that for a period of one year from the purchase date Rapid Test products will be free of defects in materials (parts) and workmanship (labour)

Defects occurring during the warranty period will be repaired or products will be replaced at Rapid Test Systems option and expense if Rapid Test Systems receives notice during the warranty period.

Defective products must be returned to Rapid Test Systems with proof of purchase date.

The product part replacement warranty is limited to replacement of parts at invoice value that prove to be defective in material content and/or workmanship under normal installations.

Cost for damages and/or labour charges incurred in installation, repair or replacement are excluded from this warranty.

Warranty Exclusions

The foregoing express warranty is made in lieu of all other product warranties, express and implied including fitness and merchant ability.

The express warranty will not apply to defects of damage due to accidents, neglect, misuse, alterations, operator error or failure to properly install products.

Limit of Liability

In no event will Rapid Test Systems or Seller be responsible or liable for special, incidental, or consequential losses or damages whether based in tort or contract.

Fulfilment of Rapid Test Systems warranty obligation will be Customers exclusive remedy and Rapid Test Systems and Sellers limit of liability for any breach of warranty or otherwise.

Contact the rapid test customer team today!

Call Us

Email Us

Free Quote

Speak to

Your Local Nhp Rep. Or Electrical Wholesaler